▼

Wednesday, November 12, 2014

Build Your Own: Swarm Trap

Here is a quick swarm trap based upon the plans for 10 Frame Deep (Minimal Tools) this is based on suggestions and previous swarm traps by Tim Ives, and some good old scientific backing from Tom Seeley.

Tom Seeley did a number of experiments on swarming behavior in his book Honeybee Democracy, which created an outline of what bees find desirable when selecting a space for a new hive.You can find a short PDF written by Seeley entitled Bait Hives for Honeybees here.

His experiments concluded that a desirable nest site for a honeybee must be: 40 litres in volume, and have an entrance of 15 cm sq.(2.325 inches) So some fancy converting and sacrificing had to be done to come up with the closest, and most practical solution. The above design, is 1/4" larger than a standard hive body. This is to accomodate no innercover (simply plywood roof), no bottom board, and still maintain beespace.

Volume:

Swarm Trap: 1.5489 Feet - 43.86 Litres

The entrance however is a little trickier. to find the radius I needed I performed the following equation

r = Square root (15cm2 area / π )

= 2.19cm

or, 0.862205 inches.

d = 2r

= 1.72441 in

Consulting a decimal to fraction sheet, gives us: 1 23/32" (1.7188) as the closest match, but good luck find a hole saw that size! So common hole saw sizes in mind our choices are limited to:

1 5/8" (1.625)

1 3/4" (1.75)

Either should work fine, but 1 3/4" is the closer match.

Conversely you could cut a slot for an entrance. This will work better for keep mice, birds and other pests out. So keeping with the theme of working with more common hand tools. Lets figure out what we need. For this youll need a drill and a jig saw, or a router with a 3/8 bit. We need to create two holes for our jig saw to get in to cut the slot, 3/8ths is beespace so lets use that.

2.325 inches - 0.11 (the area of a 3/8" circle, we need two but in the end theyll be half circles)

= 2.215"

2.215 / 0.375 (the width of our slot)

=5.9 (or six inches to keep it simple)

Homework out of the way lets get to building. Ill show the modifications to the previous design. If I leave something out refer to it.

The height of the sides has been increased by 1/4". This maintains correct beespace on the bottom and top as we are not using an inner cover or bottom board.

Next we need to add our hole. The lower on the box the better according to Seeley.

If you want to cut a slot and do not have a router, start like this. Find your middle, make a mark. Go up about an 3/4" and make a 6" line.

Next drill a 3/8" hole right at the end of each line. (the picture shows the circles radius)

Then using a dremel, thin jigsaw blade, etc. make two cuts at the top of each circle to complete your slot.

The final step is to add our floor and roof. For that find scrap plywood 16 3/4" by 21 1/8" and screw to the hive body (you will want to be able to remove the top to re hive your swarm).

Thats it for now, happy hunting!

Build Your Own - 10 Frame Deep (Minimal Tools)

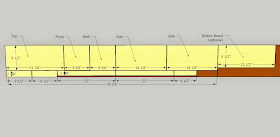

A friend of mine Bill Reynolds, who administers the Northern Beekeeping Facebook group asked me to design a simple to build hive that required minimal joinery work. Taking inspiration from the Coates Nuc Box design, we end up with a simple butt jointed box with no rabbets, dados, or fancy joinery of any kind. I elected to use barn board in combination with 3/8" plywood for added strength (10 frame deeps are much heavier than nuc boxes), as well as for a little more thermal protection. Another nice thing about this design is that with the exception of the handles, it does not matter what thickness of material you use for the sides the dimensions stay the same!

You will need

Plywood 3/8" - 4' x 8' (makes 30 pcs)Barn board (1" thick, 12" wide) - at least 38 3/8" long (you will need a little extra scrap)

Lets start by ripping down the 3/8" plywood into 9" strips (or 14 3/4" strips you will still end up with the same amount of pcs). This is best accomplished with a tablesaw, but a circular saw will work just fine (try to fashion a fence out of scrap lumber to keep your lines straight, as these will be your frame rest and dimension is critical). If you ask nicely at your local lumber yard, they might cut the strips down for you. Most good old Mom and Pops places probably will, Big box not so much.

Then cut those 9" strips down to 14 3/4", you should end up with six. Set those aside.

Next rip the barn board down to 9 5/8" strips, these will serve as the sides. Save the remaining strip as these will serve as handles.

Cut the remaining strips to 16 3/4" for the handles. You will need two extra strips of wood this length so use what scrap you have. Note: The strip is actually 1 7/8" if you use the strip from the barn board you cut.

Assemble the box as shown using wood screws. I recommend at least 2" wood screws, as these are what is carrying the weight.

Attach the plywood using screws, making sure you keep the dimensions for the frame rests as perfect as possible.

Modification

Instead of using scrap or wasting wood for the bottom strip. You can cut an extra piece of 3/8" plywood 7 3/4" by 16 3/4" to use as the front. I feel this is a stronger joint and provides better thermal protection. It does make the project more costly. Make sure you lay out your cuts on the plywood first to make the most efficient use of the material.

Note: The width of the handles is simply convenience and using the 1 7/8" strip from the barn board, they can be made out of anything you feel is strong enough for the job.

Monday, November 10, 2014

Build Your Own: Queen Rearing Cell Bar Frame

Alrighty good people, before you get started trying to build this frame, quickly give the tutorial on building your own Shoulderless Frame a glimpse. This is the same idea with a few modifications. This tutorial uses the same stock cuts as the previous tutorial, with the exception that our end bars will be using 1" by 3/4" material. Make these out of scrap.

Lets begin with the top bar. It is the same as the one in shoulderless frame tutorial, however we need to increase the depth of the cut to accommodate our thicker end bars.

The end bars are a little more complicated. Make them as per original tutorial except increase the thickness by double (3/4"). Then made your various grooves using a table saw or router. If you do not have these simply nail blocks of 3/8" wood into the required places creating the grooves (not as pretty but it works).

Our cell bars and bottom bar are made from the same wood, using the same method.

You will need one at 17 3/4" to use as a bottom board, and three at 17" to function as your cell bar.

Build Your Own - 6 Frame Nuc

This 6 Frame Nuc is designed for use with the 3 Frame by 4 Compartment Queen Castle I designed. For detailed construction information refer to the tutorial in How to Build: 5 Frame Nuc.

This 6 frame nuc is not standardized equipment. It is slightly over-sized for a six frame, however it works just fine. Use it on its own, or in conjunction with the Queen Castle I designed.

Using our favourite stock material -barn boards (also known as 1x12). Cut out the specified material. You will need a piece 8' 6 5/8".

Start by cutting out the 20 1/8" by 11" and the 21 1/2" by 10" sections crosswise with a mitre saw. Then adjust your table saw's fence to 9 5/8" and rip the rest of the material. After accomplishing this set the fence to 1 7/8" and rip the strip you just took off as well as the 21 1/2" by 10" piece. This is the most efficient way to do it. Afterward set the fence to 11 inches, and using your mitre saw finish all the required cuts.

Nuc Box

Front/Back (2) - 9 5/8" x 11"Sides (2) - 9 5/8" x 19 1/8"

Top Cover

Top - 11" x 20 1/8"Handles (2) - 11" x 1 7/8"

Bottom Board

Floor - 10" x 21 1/2"

Side Rail (2) - 1 7/8" x 21 1/2"

Back Rail - 1 7/8" x 11"

Now simply make your required rabbet joints, dado cuts, and frame rest as described in other tutorials. For the bottom board, I changed the method of construction to the one used in Build Your Own: Solid Bottom Board to maximize lumber use.

Build Your Own: Queen Castle - Three Frames by Three

This is simply for reference, follow the directions for the Two Frames by Four Queen Castle. There are a few differences.

Dividers - You will need three 1/4" dividers cut at 19 1/8" x 10 1/2"

Inner Covers - Two at 19 1/8" x 4 3/4" and one at 19 1/8" x 4 7/8"

Three frame queen castles allow the queen to build out a little more, allowing the beekeeper more time before they overflow and begin swarming preparations. If you sell nucs, a four frame nuc would simply be one of these compartments, plus a frame of empty comb/foundation. If you take out a divider you will be able to put in seven frames, however it is very tight.

If you take a Solid Bottom Board and run two dividers down the middle to the end of the landing board to correspond with the Queen Castle dividers it can make a great landing board. I know a queen breeder that uses these, and paints each divided landing board a separate colour. I could see problems with queens entering the wrong entrance. Otherwise simple cut holes on three separate sides for entrances.

Build Your Own: Queen Castle Two Frame by Four

Here is a requested Queen Castle setup. It is a modified standard deep box, so your top cover will work with it. For a bottom board the easiest method would be to fasten a piece of plywood to the bottom. If I get ambitious enough I will make plans for a fancy bottom board so you can forgo cutting holes in the box. This plan assumes you are comfortable with making your own deep, if not check out the tutorial Build Your Own 10 Frame Hive Body.

It is in principal the exact same as a deep hive body except it is taller to accommodate individual wooden inner covers, and has additional dado cuts in the front and back to accept dividers. This queen castle plan uses same size compartments as opposed to other plans that typically have odd sized ones.

You will need:

Rough Pine

Sides - (2) 19 1/8" x 10 1/2" x 7/8"

Front/Back - (2) 16 5/8" x 10 1/2" x 7/8"

Inner Covers - (4) 19 1/8" x 3 1/2" x 7/8"

Plywood Dividers

(2) 19 1/8" x 10 1/2" x 1/4"

(1) 19 1/8" x 10 1/2" x 7/16" (if you cannot find 7/16" plywood, use 3/8" or take 1/2" and sand the ends down to fit)

Floor

(1) 19 1/8" x 16 5/8" (can be made out of anything, plywood works great, just screw evenly to the bottom)

*Sorry, been way to busy making these plans I have not had time to draw out a cutlist for you.

Next create all the dado and rabbet cuts to these dimensions. This may take some time and forethought to accomplish so I suggest laying it out in pencil before attempting to cut it.

When this is accomplished take your sides (they dont need any work done to them yet) and assemble the box.

Next cut your dividers to these dimensions. You will need two 1/4" pieces, and one 7/16" (or 3/8"). Insert these into box. Do not bother fastening them. Removing them can create different spaces, and configurations to suit your needs.

Take scrap, or rip a 3 1/2" strip of 7/8" pine. Really any thickness will work for the inner covers.

Now take a drill and make a 3/4" to 1" hole for each compartment. Add your dividers attach a floor and you are on your way to making queens.

Variation

For those wanting to use a standard depth hive body. I have included these additional measurements. The inner covers sit on top of the frames, allowing bee passage underneath, whereas the above design does not allow that. This is very similar to the Brush Mountain Queen Castle.

All the measurements for your dividers remain the same. The hive body itself is standard 9 5/8" depth. You will however need to change:

Inner Cover

(2) - 20 1/8" x 4 3/8"

(2) - 20 1/8" x 3 1/2"

Sunday, November 9, 2014

Build Your Own - Medium Hive Body

I am going to cheat you guys on this one and not provide a tutorial. If you are confused follow the Build Your Own: Deep Hive Body tutorial.

The process is the exact same with the exception of a 6 5/8 depth instead of 9 5/8. I do not recommend using my typical choice of 1 by 12 rough pine as it leaves a great deal of waste. Instead call around to lumber mills and enquire if you can purchase 1 by 8 rough pine (they will probably have it).

The process is the exact same with the exception of a 6 5/8 depth instead of 9 5/8. I do not recommend using my typical choice of 1 by 12 rough pine as it leaves a great deal of waste. Instead call around to lumber mills and enquire if you can purchase 1 by 8 rough pine (they will probably have it).

Build Your Own: Insulated Top Cover

Admittedly, I haven't built this one yet. However I did design it. This is a telescoping top cover with the addition of 1.5 inches of rigid foam insulation. Its total R-Value is about R-8.75. Normal top covers have an insulation value of less than 1.

Materials

Pine (at least 3 3/4" wide, and 81 1/8" long)

Ext Plywood 3/4" - 22 1/2" by 18 7/8"

Plywood 1/4" - 22 1/4" by 17 7/8"

Like all project I am going to assume you are using our favourite barn board. So get that table saw out, and rip a strip off 3 3/4"

Discard the larger piece. Now create the recess which holds the insulation.

Now cut that strip into our required parts. You will need:

- (2) 18 7/8"

- (2) 21 1/2

That finished, it is time to assemble the basic frame using whatever fasteners you choose (nails, staples, screws, glue).

Next place the piece of 1/4" plywood (22 1/4" by 17 7/8") in the recessed area. Although it is not necessary to fasten it, I would recommend it.

Place the rigid insulation in the recess. Once again, not necessary to fasten it, but using some adhesive could be beneficial.

Fasten the plywood top, and you are away to the races. You may wish to wrap the hive in aluminum flashing for weather protection. That is a different tutorial however.

Build Your Own: Entrance Reducer

Correction: Proper length for entrance reducer is 14 1/2"

Nothing goes to waste in a beekeepers workshop! Entrance reducers can be made from commonly destined for the wood pile. This one features two different entrance, one at 1" and another at 3" depending on your needs (or the bees for that matter).

One tip, is it can be useful to taper by the top and the back side (relative to the picture). Sometimes you will find the reducer just does not want to fit (moisture in wood equals expansion). This can alleviate that problem. All it takes is a hand planer, even your hive tool or pocket knife can take off just a bit.

Just 1/16" to 1/8" can be just enough to create problem free entrance reducers. I just did the end for demonstration.

Nothing goes to waste in a beekeepers workshop! Entrance reducers can be made from commonly destined for the wood pile. This one features two different entrance, one at 1" and another at 3" depending on your needs (or the bees for that matter).

One tip, is it can be useful to taper by the top and the back side (relative to the picture). Sometimes you will find the reducer just does not want to fit (moisture in wood equals expansion). This can alleviate that problem. All it takes is a hand planer, even your hive tool or pocket knife can take off just a bit.

Just 1/16" to 1/8" can be just enough to create problem free entrance reducers. I just did the end for demonstration.

Build Your Own: Combination Bottom Board

Many supply stores now carry what is called the Combination Bottom Board. They charge an exorbitant amount of money for them, they are typically combining the idea behind a screened and a solid bottom board. They also usually feature one set of rails with various grooves cut out of them. This can make them very weak. Using the plans from both tutorials Screened Bottom Board, and Solid Bottom Board we can come up with a much better, cheaper, and more useful solution (lets not reinvent the wheel).

First take your screened and solid bottom boards.

Now put them in reverse directions, and make sure both 3/8" entrances are facing each other.

Solid Bottom Board 3/8" up

Screened Bottom Board 3/8" down

Put them on top of one another.

This leaves you with a gap of 3/4". This is exactly the space that an entrance reducer will fit into. So lets take a spare entrance reducer, and using tacks/glue/tape (whatever really) attach a mite board to it. Anything of the right size will work, cover it in vaseline or your choice of "make the mites stick the board" solution. Put the sticky board / entrance reducer into the gap. I place the entrance opening up to allow ventilation, but it is your choice.

Now we have a fancy combination bottom board without the heavy bill for one. In addition we have extra bottom boards at the apiary, a way to do mite counts, and a spare entrance reducer all in one hive. Cheers!

Build Your Own: 5 Frame Nuc

This tutorial will base itself on everything else. If you have not currently read the 10 Frame Hive Body or the Solid Bottom Board please do so. I will not be going into how to cut out the frame rest, etc so be comfortable with the previous material. You will have the option of either using 3/4" plywood for the bottom board or 7/8" Pine. I prefer the exterior ply floor, as this project uses up 7' 7 7/8" of pine board. This means

you should get 22 Nuc Boxes out of 13 twelve foot boards, a sheet of plywood, with scrap leftover.

Cost (22 Nucs):

Rough Pine x13@$1.15 (1x12x7/8) = $179.40

Exterior Plywood 1@$36.52 = $36.52

Total: $215.92

/per Nuc $9.81

The material for this is our favorite barn board 1x12x1. Plane one side down to 7/8, or buy it in 7/8s (depends on your source whether or not its 7/8" or 1")

This cut list is pretty complicated, so pay close attention. Click on the images to enlarge. (Correction, Top is 20 1/8" sorry for the confusion)

Note: Dark brown denotes scrap.

Begin by cutting your board to 79 7/8" (or 80"). Setup your fence to 9 1/2" and rip the lumber. Now you have a large piece which contains the majority of the components, and a strip that contains the handles for the top, and rails for the bottom board. Despite the plan showing 2" handles for the top cover, leaving them at 2 7/8" is fine. Cut them out of your strip.

Next, depending on whether you use 3/4" Exterior Ply for your bottom board, or 7/8" Pine you want to rip the remaining strip of wood to:

Plywood 3/4" - 1 7/8"

Pine 7/8" - 2"

Continue cutting all the components out.You should end up with

Hive Body

Front/Back - 9 1/2" x 9 5/8" x 7/8" (2)

Side - 19 1/8" x 9 5/8" x 7/8 (2)

Top Cover

Top - 20 1/8" x 9 1/2" x 7/8"

Handle - 9 1/2" x 2" x 7/8" (2) (or 9 1/2" x 2 3/8" x 7/8" if you dont rip them down, I wouldn't bother ripping them.)

Bottom Board

Side Rails - 22" x 1 7/8" x 7/8" (2) (or 22" x 2" x 7/8 if you use pine for the floor)

Back Rail - 8 1/2" x 1 7/8" x 7/8"

Floor - 21 1/2" x 8 1/2" x 3/4" (same dimensions if using 7/8" pine)

Top Cover

Simply assemble the handles to the top using screws, nails, staples, and/or glue.

Bottom Board

The side rails, and back rail will have to be grooved to accept the floor. This is covered in the previous tutorial on Solid Bottom Boards. If you elect to go with a 7/8 pine board for the floor your overall height will be 2", and the groove thickness increased to 7/8" with the 3/4" and 3/8" remaining the same.

Next rabbets are made in the side rails. Make sure to line them up and mark the tops as they are non reversible (in the tutorial I believe I rabbeted the back rails, feel free to follow either way, less mess ups doing the back rail).

Insert the floor, and assemble using your choice of fasteners.